Moderator note: This post was split from Recommended ways to expedite pho service

@chuynh

Thanks for the awesome answer. Can you provide some guidance on how I can start creating a useful service and final plating floor plan? I'm actually exploring a hybrid cooking/service area where we pass the final food to a service counter all in the open, no pass-through window or pass-through counter. My goal is to create a system when we require a minimum of staff members to serve 2 orders per minute during lunch rush. The peak is probably 130% of lunch rush.

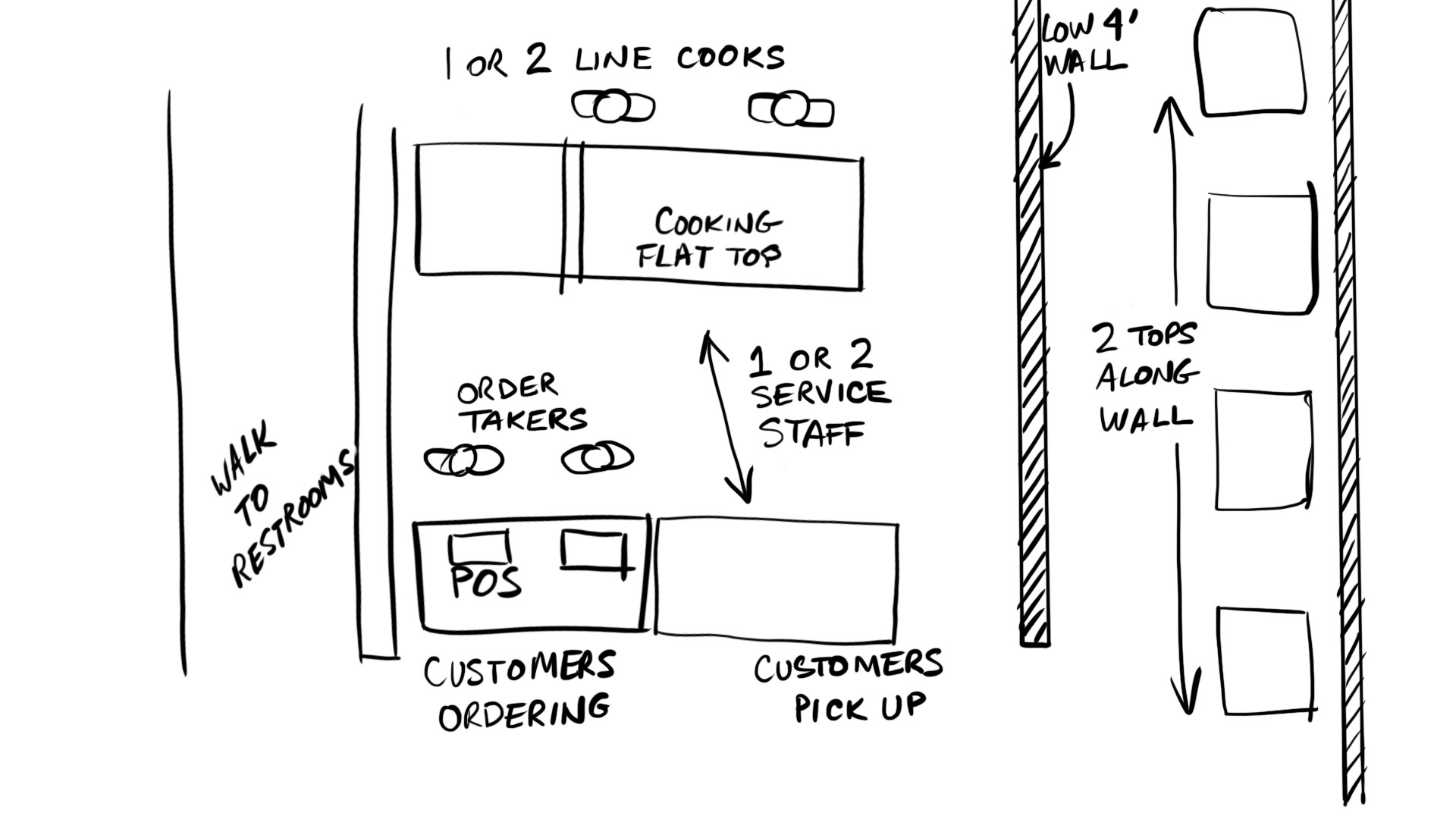

I'm attaching a sketch to show you what I'm thinking of doing. Note that it does not include a few things I consider confidential.

Thanks for any guidance.

Got your message and will take a look. I have training to give this weekend so will try to reply early next week.

Ok so first a few caveats. Providing the sketch is helpful to help us discuss the specifics instead of just glossing over general scenarios. That said, it would be even better to also provide dimensions of the space that we have to work with; many people don't realize that a few additional inches of reach or one additional step, when repeated hundreds of times over the course of days, months and years, can make a huge difference.

Anyway based on what you provided, though without knowing the specific dishes you're serving, here are some feedback.

Requirements:

- Lunch rush is 2 orders per minute = 120 orders per hour.

- Also peak is about 130% of lunch rush which means 2.6 orders per minute or 156 orders per hour.

- For regular lunch rush use the 120 orders per hour as design requirements.

- Lunch rush must be sustained for 2-3 hours.

- For peak use 3 orders per minutes or even 20 seconds per order as design requirements.

- Peak can be sporadic to constant but maybe in waves.

- When sporadic peaks become more constant, this becomes your new regular rush, and recalculate your new peaks.

- Also assume takeout orders go through the same paths, with the only difference being final packaging before service.

Design considerations:

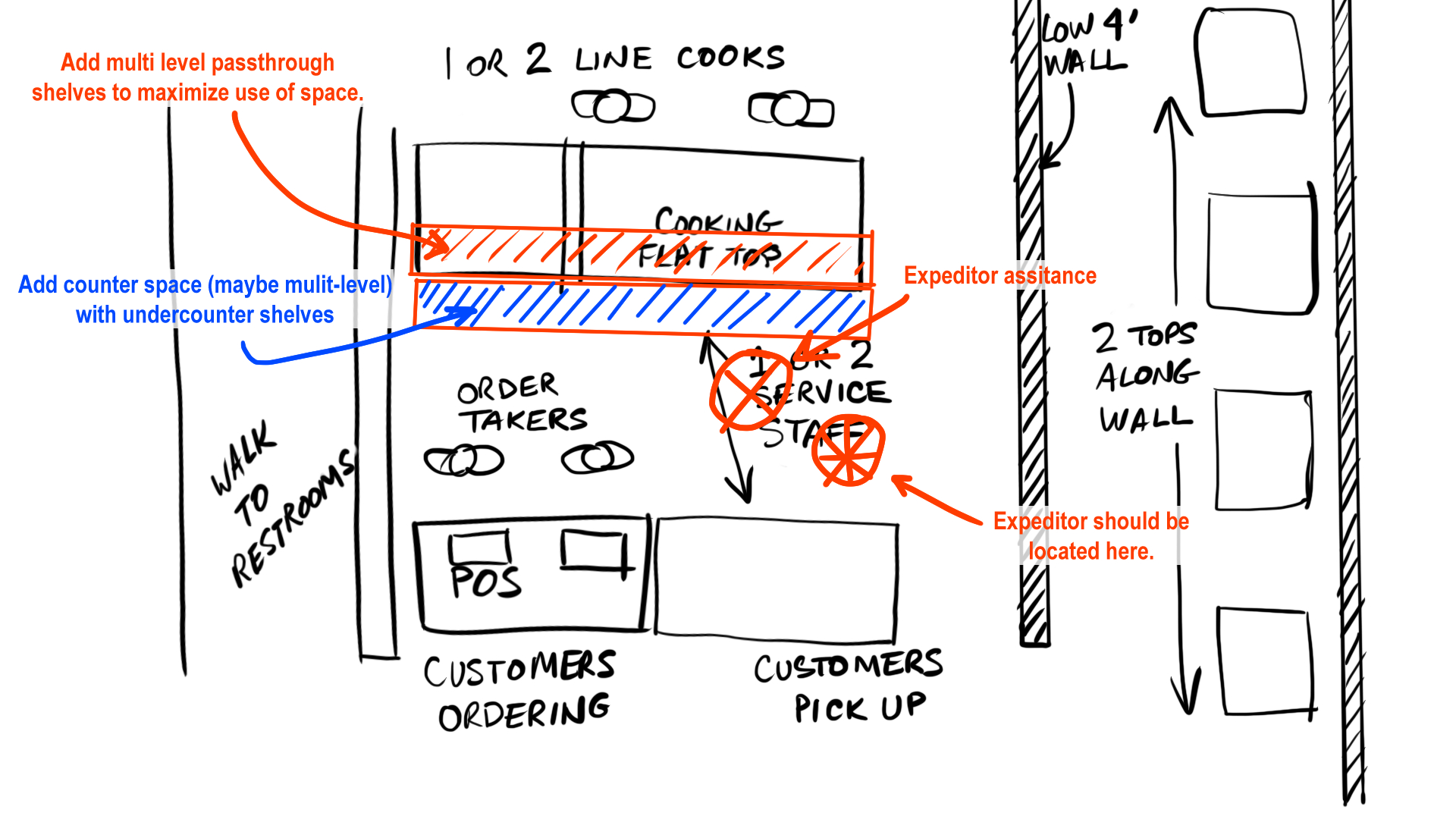

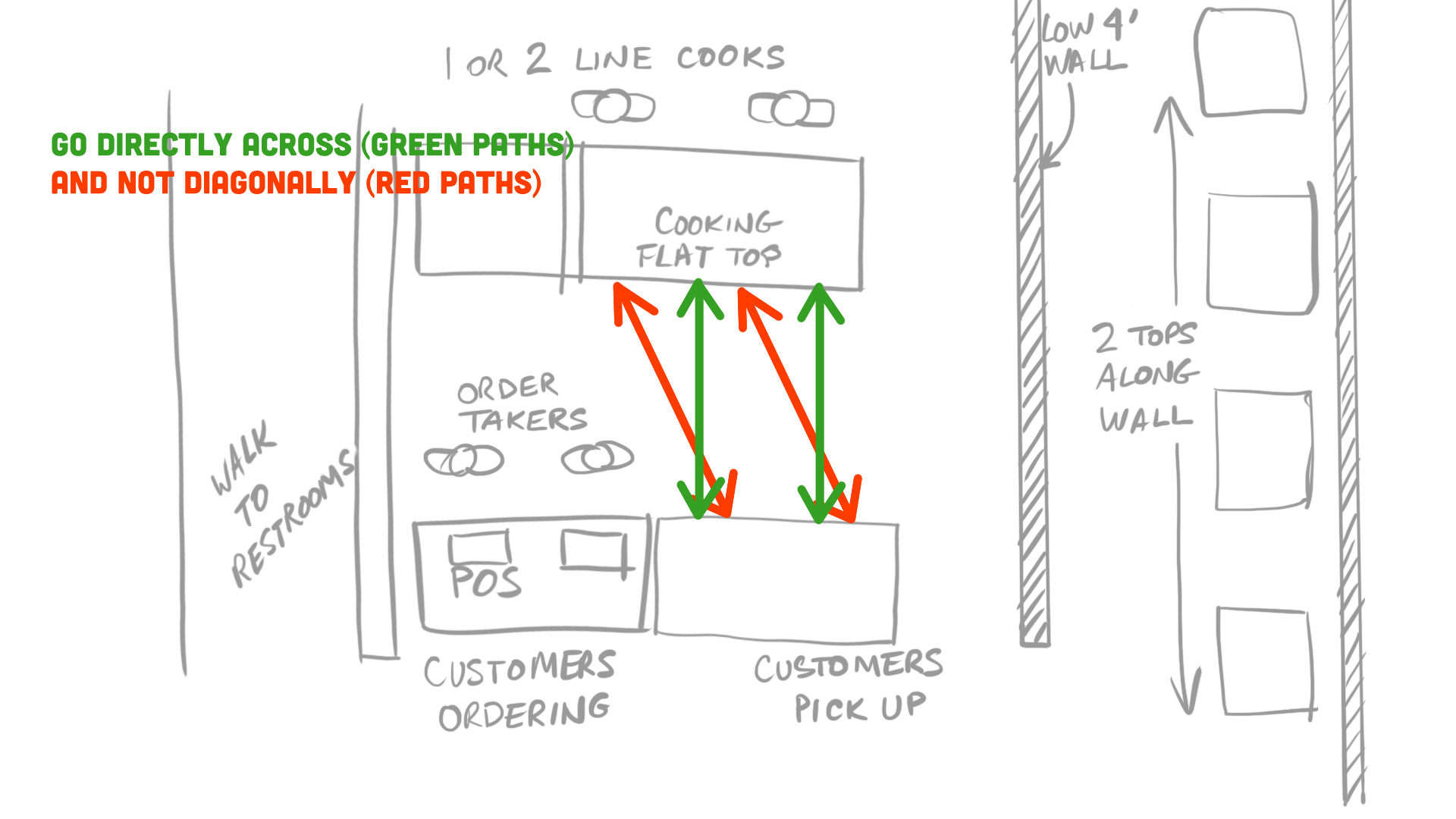

- Suggest to have an expeditor (80% customer facing) and an assistance (80% cooking staff facing).

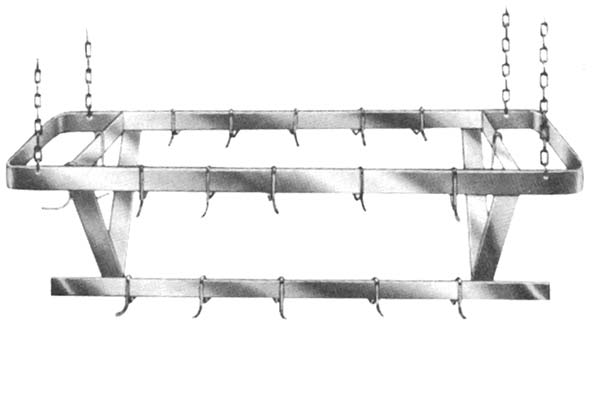

- Add multi-level shelves to allow cooking staff to more easily pass through cooked foods to the front (expeditor), while keep the cooking area clear for cooking.

- Add work counter (blue in attached drawing) with under-counter shelves to further help expediting team to inspect and finalize both eat-in and takeout orders.

- The expeditor runs everything at the pass, but focus more on customer facing tasks to ensure foods go out properly and timely.

- The expeditor assistance does everything to help final plating for expeditor approval. He/she is focused more toward making sure cooked foods come out correctly and timely as called for.

That's the gist of it. Obviously there are variations to any scenario, and this is not a "set it and forget it" task. Everything must be regularly adjusted and improved so you get better and better all the time. More critically, you must allow your staff to give feedback and suggestions. Additional variations may be needed for different traffic requirements and patterns, for simpler versus more complex menus, and for staff proficiency.

There are a lot more to this exercise. So if you truly want to have a tight operation, with staff efficiency and even satisfaction, increased quality in the products you send out, then this is the right question to ask and resolve at this early stage of your design. If we can take into account further detail such as what foods are being prepared and served; what are the specific space dimensions, equipment type, and staff level of proficiency; and eat-in versus takeout final plating or packaging, I'm pretty sure there are tons of things we can design out further.