A restaurant owner asks in another forum: Doing inventory, what would you categorize orange juice or ketchup as?

He mentions he has the following inventory categories already set up in the restaurant: meat, dairy, fruits and veggies, dry goods, alcohol, restaurant supply (plates, glasses utensils, etc.)

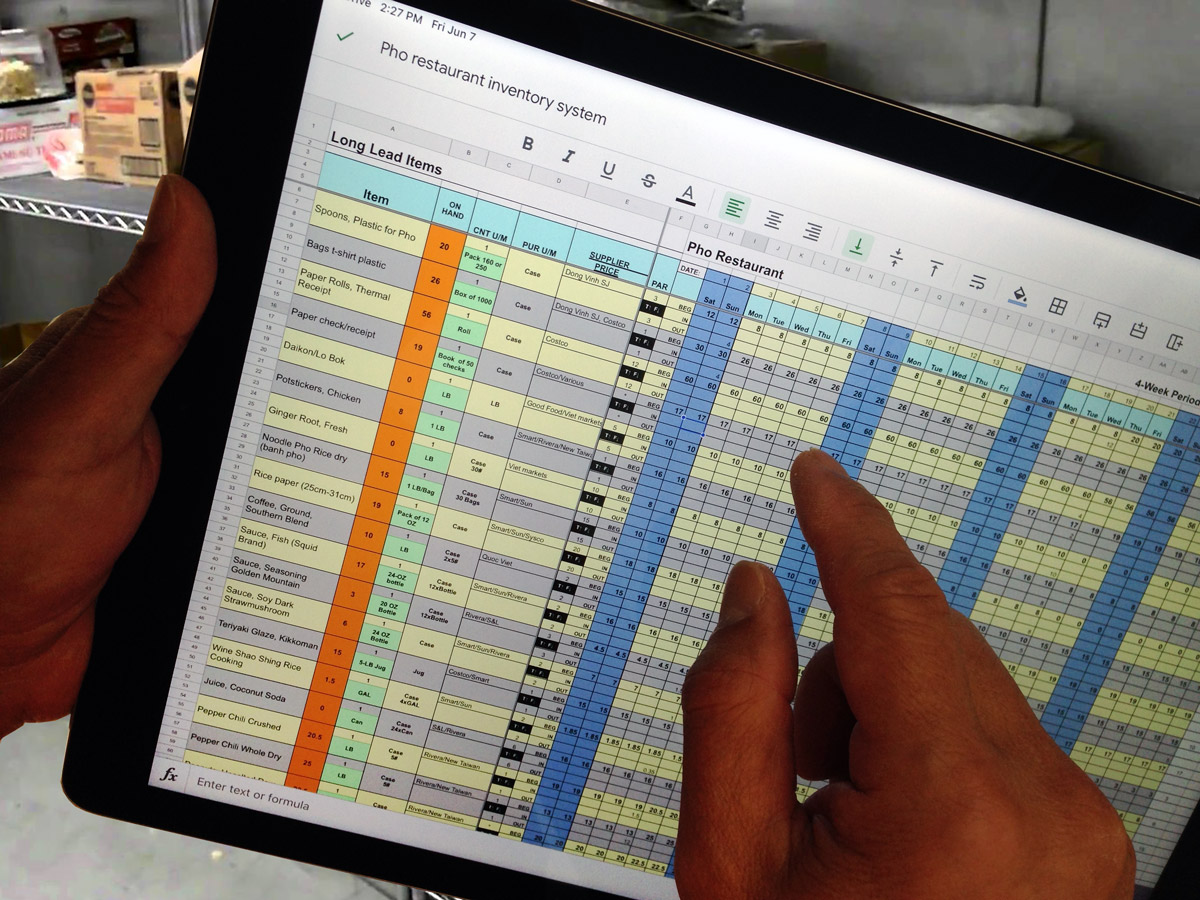

Below are my tips and suggestions for this operator. While this is not a pho restaurant, the idea behind having the right inventory system with the right implementation applies to all restaurants, pho restaurants included.

Purpose of an inventory system

Inventory system should be designed to meet a restaurant's operational goals. It's not just for counting purpose, but what the counting is used for or what key performance indicators (KPIs) you're trying to meet. For a properly designed inventory system (IS) to work well, it should allow you to do these 2 things at a minimum:

- Accurately, quickly and efficiently track your inventory, and

- Utilize the collected data to run your pho restaurant business better, more profitably, or allow you more efficient ordering process, or tracking food cost for Prime Cost calculation, or even ensure food quality with proper stocking and rotation or first-in first-out (FIFO).

Regarding orange juice and ketchup

In this case study, if you have categories already set up as meat, dairy, fruits/veggies, dry goods, alcohol, restaurant supply, then any item purchased must fit within these existing categories. If you have an item that you don't know how to inventory, then it's clear the inventory system hasn't been very well thought out and built.

You definitely don't want to keep adding new categories (read, making it up) as you go, because before long, you'll have a mess on your hand. And once this happens, you'll get frustrated and stop doing inventory all together, it becomes "too complicated!"

To the owner asking the question, someone suggests to put the OJ in with the "liquids" category and the ketchup with the "condiments" category.

Someone else recommends the OJ as part of "beverages" and ketchup in both the "sauces" and "condiments" categories.

Clearly the result of the above suggestions is a growing and messy inventory system. The reason: everyone has different motivation and thinks differently about different things; they don't think about what's appropriate for this particular restaurant, what is already in use, and how to conform to the policy and system already in place.

It's OK to be arbitrary

The suggestions clearly didn't consider this particular owner's own system that is already in place. As a result these suggestions don't really help much. Of course OJ is a liquid but it's also a beverage, and ketchup is both a condiment and a sauce. So unless you have a sophisticated system (and good reasons) to categorize a product in multiple categories, the reality is this is most often an arbitrary choice. And for inventory it's ok to be arbitrary. You just have to be consistent. If 50 people suggest 50 ways to add these items, then they are just giving the owner a bigger headache.

This is not to say that you can't ever change the system you already have. However, a change and its implication or impact on the operation has to be understood before such change is allowed.

So as an owner, before you ask the mass or anyone for help, make sure you understand that the mass neither necessarily provide useful help nor always has your best interest in mind. They may just want to show off how smart they are, and you end up spending more time wading through numerous (often worthless or irrelevant) recommendations before finding that one thing that works for you.

The right way to categorize orange juice and ketchup in this restaurant

To do this right, I'd suggest the following, based purely on the existing system the owner has already set up:

- If OJ is frozen, then it goes to meat (freezer) on proper shelves.

- If OJ is room temp shelf stable, then it goes to dry goods (same place as other shelf-stable liquids/sauces).

- Ketchup (bags or bottles) should go to dry goods (with shelf-stable liquids/sauces).

Additionally, I suggest the owner may want to rename some categories, or even add a few to accommodate quicker and more efficient inventory process. The currently existing categories as it is may be too limited and inefficient.

More importantly, the owner needs to have inventory rules and policies clearly defined and in place so that the system is clean and lean, the data is highly reliable and useful, and taking inventory regularly can be done quickly and efficiently.

Remember, speed and accuracy is both important.

Categorizing inventory by locations

A good method of doing inventory management is to inventory by location rather than, or in addition to, categories. This means you can store bulk ketchup for cooking in the back of the house (BOH), and pre-portioned ketchup for condiments closer to the front of the house (FOH).

What this does is it forces you to recognize that ingredient items may come in various shapes, sizes, forms, and purposes that need to be counted separately. You are actually buying them as different and separate things and you are using them differently in your business. This is exactly how your suppliers organize their inventory as well.

With location as one of the inventory dimensions, you can think of it as a multi-dimensional matrix. You would have something like

[list of ingredients x categories x locations]

as opposed to a 2-d matrix of

[list of ingredients x categories].

Whether you identify an item in a database or a spreadsheet, you must identify it by all its important and relevant dimensions.

To illustrate this, check out the table below as we use OJ and ketchup as sample ingredients:

Inventory Category and Location Breakdown Example: OJ and Ketchup

| Ingredient Item | Vendor Detail / UM* | Ingredient Inventoried As | Category | Location | Count / UM** |

|---|---|---|---|---|---|

| Orange Juice, Frozen | Vendor UM*, Case of 24 x 8 FL-OZ Carton, Concentrated, Frozen | Orange Juice, Frozen, Concentrated | Sauces | Back Freezer, Walk-in | 18 / Cartons |

| Orange Juice, Fresh | Vendor UM, GAL, Fresh Squeeze, Ready to Consume | Orange Juice, Fresh, Service | Beverages | Front Cooler, Reach-in | 5 / GAL |

| Orange Juice, Shelf Stable | Vendor UM, 1/2 GAL, Shelf Stable | Orange Juice, Shelf Stable | Sauces | Dry Storage Room, Back | 6 / GAL |

| Ketchup, Bulk | Vendor UM, Bag 3 LBS, Bulk Ketchup | Ketchup, Bulk | Sauces | Dry Storage Room, Back | 9 / LBS |

| Ketchup, Bottle | Vendor UM, Case of 60 x 2.25 FL-OZ Bottle | Ketchup, Bottle | Sauces | Front Storage Area | 25 / Bottles |

| Ketchup, Packet | Vendor UM, Case of 500 x 9 Gr Packet | Ketchup, Packet | Sauces | Front Storage Area | 3.25 / CASE |

| * Vendor UM is Unit of Measure used by vendor ** Count UM is Unit of Measure used by restaurant internally | |||||

As can be seen, if you clearly plan it out, you'd recognize that both OJ and ketchup may actually 3 different products, depending on how you use them, what your recipes are calling for, and how you plan to service or sell them. Once you set it up this way, you can do inventory very quickly without confusion and cross counting.

Note that each ingredient itself has its own multiple dimensions such as different prices from different vendors, or similar/second choice if first choice is unavailable, or varying packaging sizes for same item or brand, etc.

The real purpose of doing inventory right

Operationally, I'd suggest inventory by location because it's the fastest and most accurate way to count. Further implementation of other techniques will speed it up even more. We'll discuss these in future posts.

Once you have everything counted, utilizing categories will get you (again with speed and accuracy) all financial parameters necessary to run your restaurant (ordering, running specials, marketing & promotions, calculating Prime Cost, etc.)

Three more important notes:

Your inventory system should use the concept of unit of measures (UM). You will order and take delivery of ingredients in VENDOR UMs, but once inside your system (restaurant), you need to control ingredients/assets via your own internal UMs. I won't go too much into this here at this time but in most cases your own UMs should track with or be driven by your recipes, which is why they're often called Recipe UMs. Of course conversion between the two UMs should be necessary, but it is pretty straightforward and easy.

Your inventory system must have all control gates identified for each storage location. It could be a door (for a room, walk-ins, or standalone refrigerator) or an imaginary planes (for areas with free standing racks or shelves in the open). Any item crossing the control gates will need to be inventoried, either in or out. This way there should be no question of whether to inventory something, when to do it and how.

Lastly, set up your FIFO system and get everyone to adhere to FIFO everywhere as standard practice.

These should get you on the right track of setting up and running a solid inventory system for your pho restaurant.

Read all inventory articles: